- #Linuxcnc freecad download software#

- #Linuxcnc freecad download code#

- #Linuxcnc freecad download free#

The output from FreeCAD, STL, STEP, SVG, or DXF, can be sent to any of the CAM programs listed below.

It's not necessarily what we'd recommend for a beginner, but it is free, so there's no cost to try it. Like Alibre, it's capable of creating very complicated designs with very high precision, but the user interface is much more complicated, and the learning curve will be much more difficult.

#Linuxcnc freecad download free#

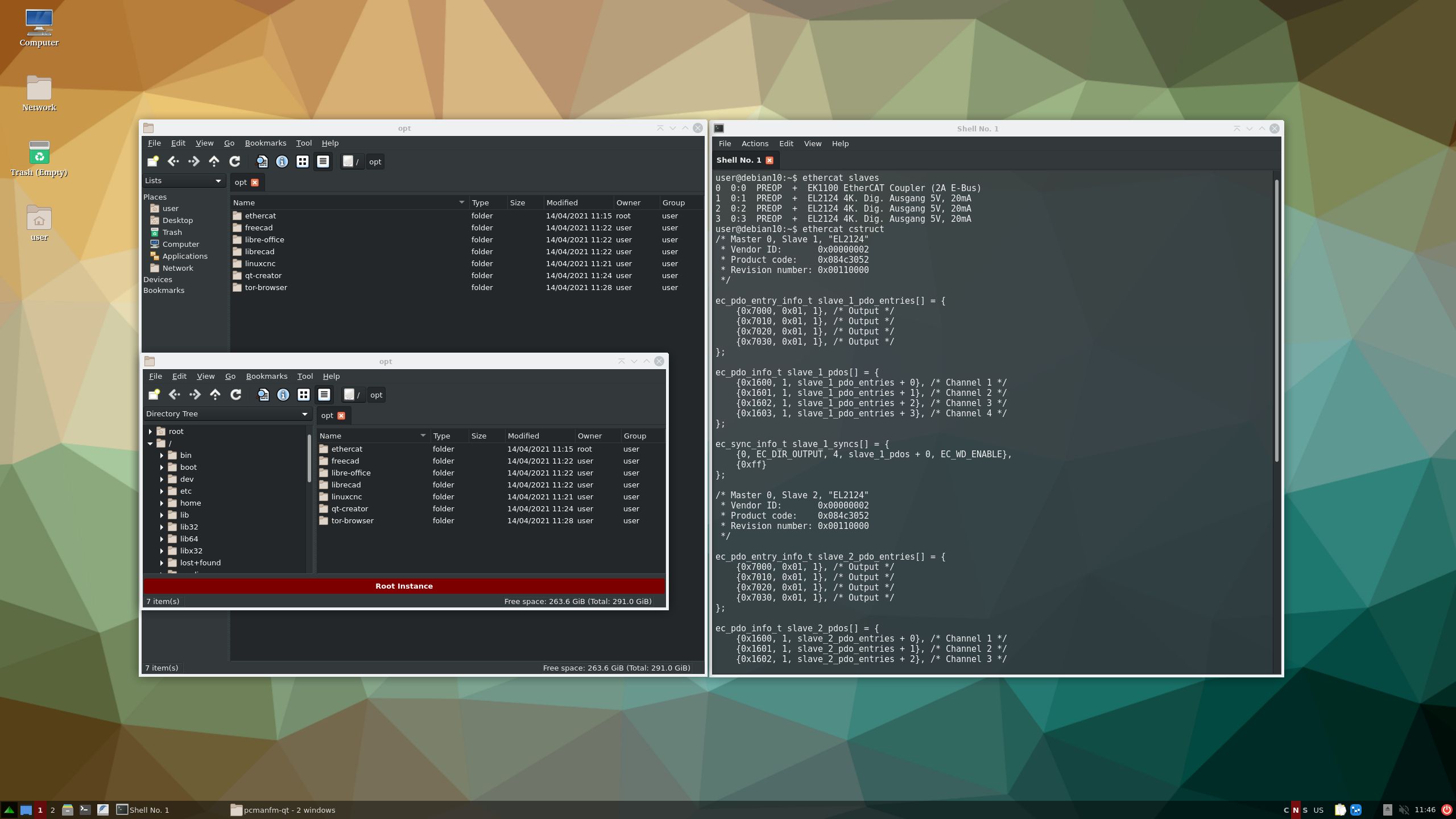

FreeCADįreeCAD is a completely free 3D CAD parametric program that's become increasingly popular as 3D printers have become more popular. Luckily there have been significant improvements in the free options over the past few years as 3D printing, which uses the same CAD program, has taken off.

#Linuxcnc freecad download software#

There are many CAD software packages out there, but unfortunately, most of them are not free. Free CAD softwareĬAD, which stands for Computer-Aided Design, is the CNC software that lets you draw your designs. We'll limit our listing to software for a CNC router or CNC milling machine and avoid other machine types, like plasma cutters and laser cutters. You may spend more time with the software than your CNC mill, so it's worth spending a few dollars if the paid software makes CNC machining easier. We'll cover a few paid products in addition to free options.

#Linuxcnc freecad download code#

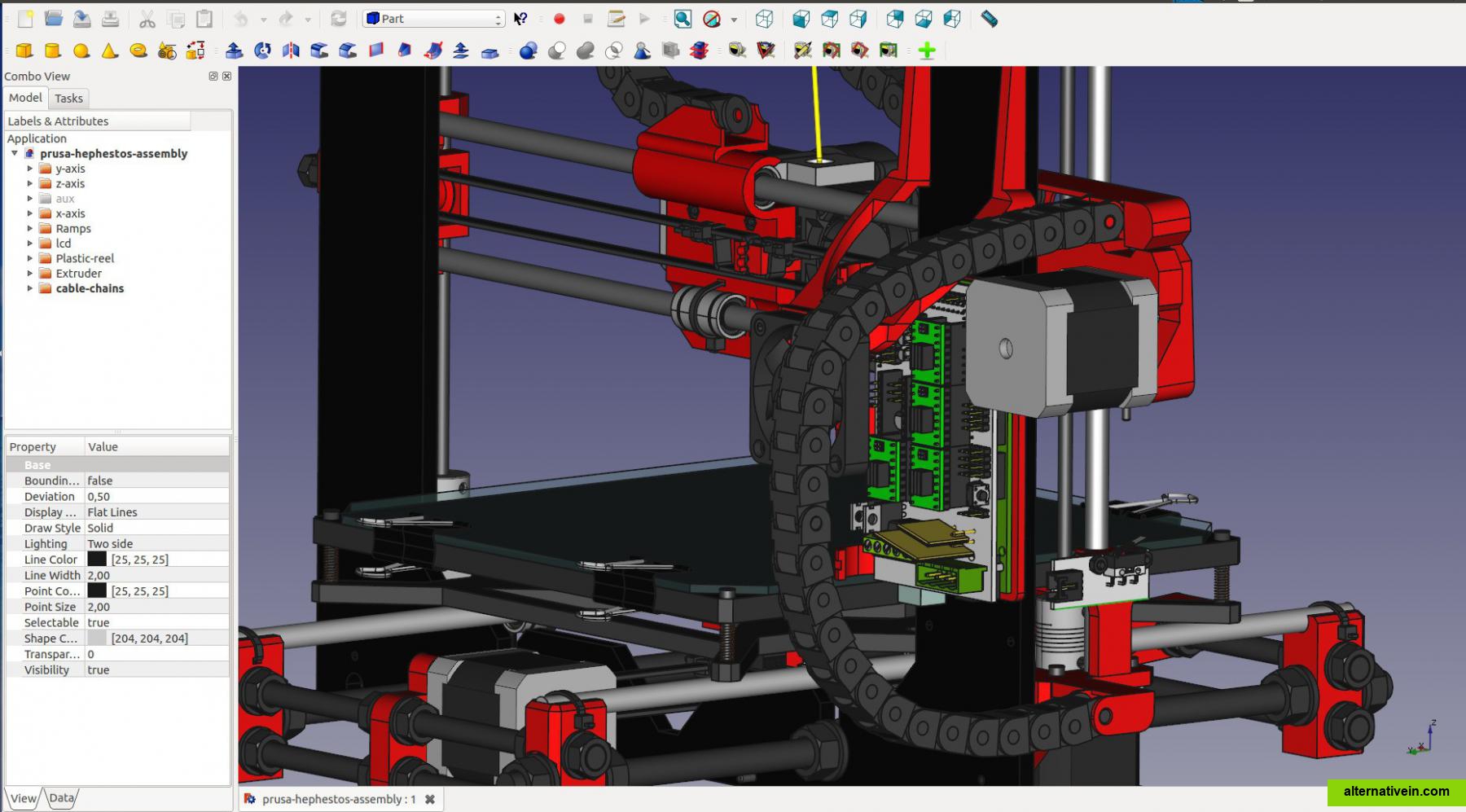

Make sure it is the tool itself moving along this path, i.e. Prepare it with any program suitable for your machine.Ī file for such paths starting at (0,0,0) and going towards Y would be helpful. You may start with a very simple model showing how your machine reads straight lines and arcs. Preparation for writing your own postprocessor The postprocessor is a program which translates the internal codes into a complete file, that can be uploaded to your machine. you might wish to include a custom header to identify or document the program for future reference.įurthermore there are other languages to control a mill, such as HPGL, DXF, or others.you might wish to include comments for readability or suppress them to keep the program small.it might be useful to perform a set of moves prior to calling for a tool change to make the action easier for the operator.you might prefer your G-code output in either metric or imperial units.it can used so called canned cycles for predefined subprocesses such as drilling.it may require line numbers in a certain format.arcs can be defined with a relative or an absolute center.the machine can have a special startup sequence.They may look almost like the internal codes, but there may be some differences: Many mills use G-codes as well to control the milling process. More sophisticated curves such as B-splines are already approximated by FreeCAD's Path Workbench. These movements are rather simple: They can be straight lines or they can be circular arcs. But the most important thing is the movements they describe. They can describe such things as: speed and feed rates, stopping the motor etc. 3 Preparation for writing your own postprocessorįreeCAD uses as internal representation for the generated paths, so called G-codes.2 What the postprocessor can do for you.

0 kommentar(er)

0 kommentar(er)